What is IP rating for an HMI?

Date: 10/09/2023

IP RATING: MEANING AND DEFINITION

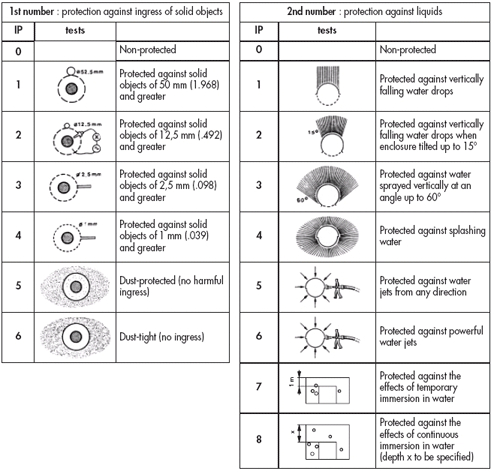

IP rating was defined in international standard IEC 60529. This index is used to define levels of sealing effectiveness of electrical enclosures against the intrusion of liquids, solid objects (which can be body parts such as hands and fingers) and dust.

An IP rating consists of two digits:

First Digit: Indicates protection against solid objects (e.g., dust, debris).

Second Digit: Indicates protection against liquids (e.g., water, oil).

According to the Ip certification chart, IP 67 means the device is completely protected against dust (first digit 6) and protected against the effects of temporary immersion in water (second digit 7)

The two digits can be followed by an optional letter like “K”. IP69K is the maximal level of sealing according to the IP code (Ingress Protection Rating). The IP protection rating of HMIs will therefore vary according to how waterproof and dustproof they are.

IP RATING TABLE: UNDERSTANDING PROTECTION LEVELS

Rating | Protection Against Solids | Protection Against Liquids |

|---|---|---|

IP00 | No protection | No protection |

IP20 | Protected against solid objects >12.5 mm (e.g., fingers) | No protection |

IP40 | Protected against solid objects >1 mm (e.g., wires) | No protection |

IP54 | Protected against limited dust ingress | Protected against water spray from any direction |

IP65 | Dust tight (complete protection against dust) | Protected against water jets from any direction |

IP67 | Dust tight | Protected against temporary immersion in water up to 1m depth for 30 minutes[JT1] |

IP68 | Dust tight | Protected against continuous immersion in water beyond 1m depth, as specified by the manufacturer |

IP69K | Dust tight | Protected against high-pressure, high-temperature water jets from multiple angles |

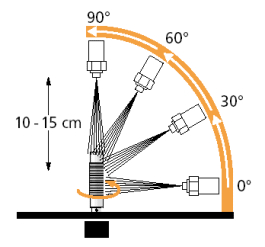

IP69K TEST TO MESURE THE SEALING OF HMIS

The goal of this test is to simulate pressure cleaning conditions on a plant floor. In the test fixture, the switches German standard DIN 40050-9 extends the IEC 60529 rating system with an IP69K rating for high-pressure, high-temperature wash-down applications. Such enclosures must not only be dust tight (IP6X), but also able to withstand high-pressure and steam cleaning.

The IP69K test specification was initially developed for road vehicles, especially those that need regular intensive cleaning (dump trucks, cement mixers, etc), but also finds use in other areas (e.g., food industry). An HMI that passes the IP69K test is guaranteed to be perfectly impervious to liquids and dust.

A FEW EXAMPLES OF OUR IP69K SEALED PRODUCTS:

SOME APEM IP67 SEALED PRODUCTS:

MAIN APPLICATIONS WHERE IP RATING PROTECTION IS NECESSARY

MAIN APPLICATIONS WHERE IP RATING PROTECTION IS NECESSARY

Construction machinery: construction sites are constantly exposed to dust, moisture, and debris. Site machinery is often left outside overnight, exposed to damp and rain. A strong IP rating protection ensures that HMIs remain operational under these harsh conditions.

Agricultural machinery: Agriculture machinery operates in environments where exposure to dirt, water, and pesticides is routine. Proper sealing not only prolongs the lifespan of the equipment but also ensures consistent performance during vital agricultural processes, such as planting and harvesting, which is critical during peak operational periods in the agricultural cycle.

Defense: in this sector, the reliability of equipment can be a matter of life and death. Devices used in these settings must operate without failure and be able to withstand extreme environmental conditions, including exposure to water, dust, and chemicals.

New mobility : High IP-rated HMIs are essential in this sector. Indeed, vehicles operating in various environments like city streets or rural roads must be protected against dust and water. In Electric vehicle charging stations, IP-rated interfaces ensure durability and safety, even in harsh weather.

Contact Us

Get the help and resources you need quickly with APEM

If you have questions or suggestions, we’re here to listen.

Our sales and support set the standard for helping you.

All the technical documentation you need to make things work...