What is the IK impact resistance rating?

Date: 10/09/2023

Definition and features of IK rating

The IK rating defines the degree to which a product can resist impact forces and appears frequently in technical documents. Originally part of the IP sealing tests, the IK rating became its own distinct measure in 1995 under the EN 62-262 European standard. It specifically assesses the impact durability of materials used in human-machine interfaces (HMIs) like the anti-vandal pushbutton switches AV 250, which adhere to IK standards. Ratings range from IK00, indicating no protection, to IK10, which protects against impacts as severe as 20 joules—similar to a 5 kg mass dropped from 400 mm. Selecting HMIs with appropriate IK ratings ensures they can withstand the physical demands of their operating environments.

Functioning of the IK impact test

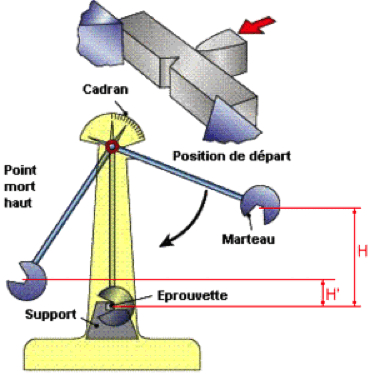

This rating can be decisive in a product selection. It doesn’t rate the mechanical life but the capacity of a product to face environmental aggressions. Therefore, it is a key feature for any product intended for consumer goods. The IK impact resistance is rated through a specific test carried out with a “Charpy pendulum” impact tester. This device measures the resistance of a product submitted to 3 repeated identical impacts. The impact energy (in joules) depends on 2 elements:

The distance between the hammer and the tested sample

The hammer weight. According to the resistance level rated during the test, an IK code is assigned to the product. This code ranging from IK0 to IK10, determines the energy level the product can absorb.

Applications where impact resistant HMIs are the most useful:

Agricultural Machinery: In the agricultural sector, equipment is frequently exposed to harsh outdoor conditions, including heavy impacts from tools, debris, and rough terrain. HMIs with a high IK rating are essential to withstand these physical stresses, ensuring reliable operation and longevity of the machinery. The durability provided by a high IK rating helps maintain the efficiency of agricultural processes by minimizing downtime due to HMI damage.

Construction Machinery: In the demanding environment of construction sites, equipment is continually exposed to potential hazards such as falling objects, accidental impacts, and abrasive materials. For Human-Machine Interfaces (HMIs) operating in such conditions, a high IK rating isn’t just beneficial—it’s essential. These HMIs are designed to withstand considerable physical damage, which is vital for maintaining uninterrupted operation. The robustness provided by a higher IK rating ensures that these interfaces can reliably manage the rigors of construction work, supporting both safety and productivity on site.

Material Handling: In material handling applications, such as in warehouses and logistics centers, HMIs are often installed on forklifts, cranes, and other handling equipment. These environments are prone to collisions, knocks, and other forms of mechanical stress. High IK-rated HMIs are necessary to endure these impacts, ensuring that the control systems remain operational and preventing costly interruptions in the material handling process.

Defense: The defense sector demands HMIs that can perform reliably under the most extreme conditions, including combat environments where equipment may face intense impacts, vibrations, and shock. High IK-rated HMIs are essential in this field to ensure that mission-critical systems remain functional, regardless of the physical challenges they encounter. The robustness of these interfaces is vital for the safety and success of military operations.

Popular APEM products with a high IK rating :

IK Rating Impact Levels

Here is a concise table showcasing the different IK ratings, detailing both the protection each offers and their real-world impact scenarios:

IK rating | Protection | Equivalent Impact |

|---|---|---|

IK00 | Not protected | |

IK01 | Protected against 0.14 joules impact | Equivalent to impact of 0.25kg mass dropped from 56mm above impacted surface. |

IK02 | Protected against 0.2 joules impact | Equivalent to impact of 0.25kg mass dropped from 80mm above impacted surface. |

IK03 | Protected against 0.35 joules impact | Equivalent to impact of 0.25kg mass dropped from 140mm above impacted surface. |

IK04 | Protected against 0.5 joules impact | Equivalent to impact of 0.25kg mass dropped from 200mm above impacted surface. |

IK05 | Protected against 0.7 joules impact | Equivalent to impact of 0.25kg mass dropped from 280mm above impacted surface. |

IK06 | Protected against 1 joule impact | Equivalent to impact of 0.25kg mass dropped from 400mm above impacted surface. |

IK07 | Protected against 2 joules impact | Equivalent to impact of 0.5kg mass dropped from 400mm above impacted surface. |

IK08 | Protected against 5 joules impact | Equivalent to impact of 1.7kg mass dropped from 300mm above impacted surface. |

IK09 | Protected against 10 joules impact | Equivalent to impact of 5kg mass dropped from 200mm above impacted surface. |

IK10 | Protected against 20 joules impact | Equivalent to impact of 5kg mass dropped from 400mm above impacted surface. |

IK rating chart classifying IK ratings. |

This table helps you choose the right HMI based on the level of impact protection required for your specific applications.

Contact Us

Get the help and resources you need quickly with APEM

If you have questions or suggestions, we’re here to listen.

Our sales and support set the standard for helping you.

All the technical documentation you need to make things work...