APEM, your source for custom industrial controls with vertical manufacturing integration

Date: 17/02/2025

Loading...

In the competitive world of HMI manufacturing, the ability to adapt and innovate is key to staying ahead. APEM, a global leader specializing in industrial Human-Machine Interfaces (HMIs), has built its success on two standout qualities: highly customizable HMI solutions and integrated manufacturing processes. Discover how APEM utilizes its extensive global production facilities to enhance flexibility, quality, and reliability, providing customers with some of the best solutions on the market.

The strength of vertically integrated manufacturing

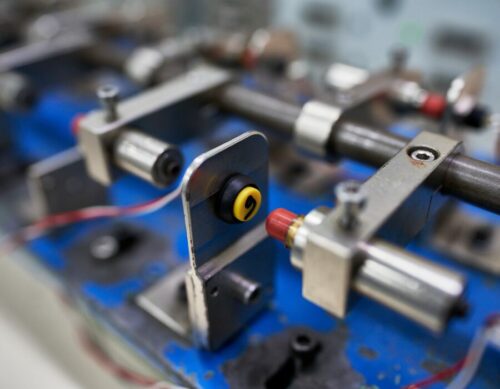

APEM’s manufacturing prowess is evident in its ability to produce everything from simple switches to complex integrated HMI solutions across its global production sites. Equipped with state-of-the-art machinery, APEM seamlessly adapts to varying customer projects, incorporating cutting-edge embedded technologies, diverse design options, and scalable volume production.

One of the critical pillars supporting APEM’s manufacturing strength is its control over every stage of production. This vertical integration starts with the transformation of raw materials and extends to the final product assembly. By producing the majority of components in-house, APEM ensures a consistent level of quality across all production stages, adhering to QRQC (Quick Response Quality Control) methods.

From raw materials to finished products

Every HMI that leaves an APEM plant is the result of a meticulously documented and controlled process, encompassing:

Tool Design and Maintenance: All plastic injection molds and tools are designed and maintained in-house.

Industrialization Phases: From initial prototypes to mass production, APEM oversees all industrialization phases.

Turning and Stamping: Utilization of hand lathes, hydraulic presses, CNC, and CAM-type machines.

Molding: High-volume parts production with materials like thermosets, thermoplastics, silicones, and elastomers using Arburg and Engel molding machines.

Surface Treatment: Application of metals such as nickel, gold, silver, and palladium, with radiographic testing for quality assurance.

Printing and Cutting Technologies: Digital printing, screen printing, blistering, embossing, and laser cutting for control panels.

Assembly Processes: A mix of manual, semi-automatic, and fully automated assembly, including product wiring, marking, printing, and engraving.

Complex HMI Integration: Capabilities to integrate communication protocols (CAN, RS485, RS422, USB) and manage custom displays (LCD screens, 7-segment displays, NVIS LEDs).

Quality Testing and Inspection: Rigorous testing in in-house laboratories and specialized labs for qualifications such as VDE, ATEX, CECC, and MIL spec.

Flexibility: the key to custom HMI manufacturing

APEM’s commitment to customization is evident in its flexible production lines, capable of meeting unique customer specifications. The predominantly manual assembly process allows for rapid adjustments, enabling the production of diverse and highly customized HMI solutions. This adaptability ensures that APEM can consistently deliver products tailored to the specific needs and branding requirements of its clients, regardless of complexity.

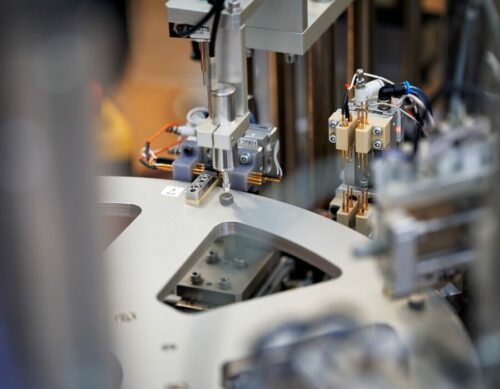

Sustaining high-volume HMI production

APEM’s ability to produce complex HMI solutions in high volumes over extended periods is a testament to its robust production capabilities and trusted customer relationships. For projects requiring large quantities over long periods, APEM develops custom-made assembly and testing machines tailored to the client’s needs. This collaborative approach ensures an optimal balance between manual labor and automated processes, maximizing productivity and quality.

In partnership with customers, APEM designs and implements bespoke robotic machines that enhance the manufacturing process and ensure the integrity of produced parts. This dedication to customized solutions ensures that clients receive Human-Machine Interfaces that are not only tailored to their specific applications but also built to endure the most extreme usage conditions.

APEM’s unique blend of customization and vertically integrated manufacturing sets it apart in the HMI market. With a proven track record of delivering high-quality, tailored solutions, APEM continues to support its clients’ diverse human-machine interface needs, from the simplest to the most complex custom industrial control panels. Trust APEM to provide robust, customized HMI solutions that meet your specific application and branding requirements, ensuring exceptional performance in any environment.

ASK FOR A SAMPLE OR INFO

Sign up to receive our newsletter, emails about special offers, updates and new releases.

You might be interested in this

TREND

2024/05/02

Get the help and resources you need quickly with APEM

If you have questions or suggestions, we’re here to listen.

Our sales and support set the standard for helping you.

All the technical documentation you need to make things work...