From manual to motorized: reduce strain with electric trolley assistance

Date: 20/06/2025

Loading...

In industrial, logistics, and healthcare environments, workers often push and pull heavy loads throughout the day. These repetitive manual tasks contribute to fatigue and strain, affecting both well-being and productivity. According to the European Agency for Safety and Health at Work, musculoskeletal disorders (MSDs) represent over 60% of all workplace illnesses in the EU.

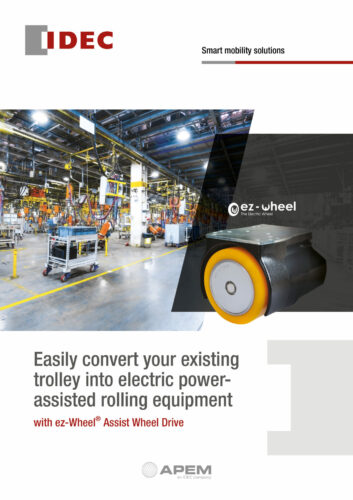

At APEM, we design ergonomic and intuitive human-machine interfaces that support more comfortable, efficient operations. As part of the IDEC Group, we bring you AWD® Assist Wheel Drive — an electric wheel system that adds motorized assistance to existing trolleys. No redesign, minimal disruption — just smoother movement and less physical effort for loads up to 1 000 kg, even on slopes.

AWD®: ELECTRIC ASSISTANCE WHERE IT’S NEEDED MOST

AWD® is a compact, plug-and-play motorized wheel designed to retrofit existing carts and rolling equipment. Once installed, it allows operators to move up to 1 000 kg with only 35 daN, staying within ergonomic thresholds and improving day-to-day working conditions.

There are two models to suit your environment:

AWD® 150 – IP43, shock-resistant, ideal for industrial use

AWD® 160 – IP66, silent and hygienic for hospitals and cleanrooms

KEY ERGONOMIC BENEFITS:

Less physical strain on backs, shoulders, and arms

Safer handling on ramps, turns, and slippery floors

Easier operation for all users, regardless of strength

Fewer injuries and sick leaves — better team well-being

INTUITIVE CONTROL WITH APEM INTERFACES

AWD® wheels can be driven using APEM’s reliable, user-friendly controls:

Both models are compatible with AWD® 150/160 and the EW9Z-1ACxM control module — combining mechanical support with electrical integration.

A FAST, SCALABLE UPGRADE

Unlike full AGV or robot solutions, AWD® requires no redesign or downtime. Most installations can be completed quickly using kits, with battery options (internal or external) tailored to each use case. It’s an accessible first step toward smarter mobility.

“How to retrofit your trolley with AWD®“

READY TO ADD ELECTRIC ASSISTANCE TO YOUR FLEET?

Let’s explore how AWD® can reduce strain and improve comfort in your daily operations.

Would you like to review technical documentation or evaluate integration options?

Talk to an expert about your handling challenges.

Sign up to receive our newsletter, emails about special offers, updates and new releases.

Get the help and resources you need quickly with APEM

If you have questions or suggestions, we’re here to listen.

Our sales and support set the standard for helping you.

All the technical documentation you need to make things work...