Industrial remote control and teleoperation technology for connected vehicles

Date: 18/11/2025

Loading...

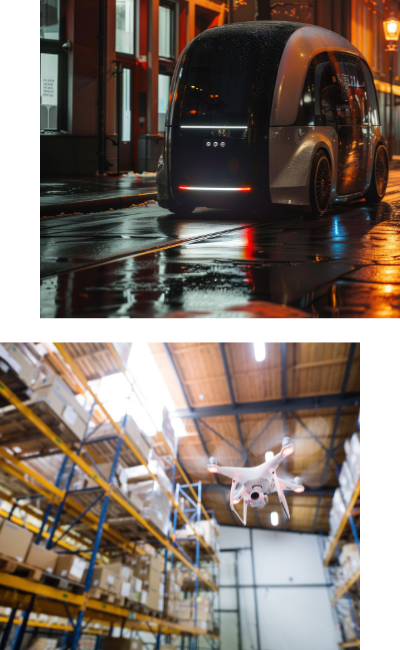

From agriculture to defense, industrial vehicles are increasingly operated remotely through advanced remote-control systems. These technologies, combining wireless control systems, radio remote control, and teleoperation technology, enable operators to supervise machines from a safe distance while maintaining full precision and responsiveness. In AGV, UGV, UAV and other connected vehicle applications, industrial remote-control interfaces such as joysticks, remote controllers with receivers, and HMI remote panels are redefining how humans interact with automated equipment.

What is a remote-controlled vehicle?

A remote-controlled vehicle is any machine that can be operated at a distance using a remote-control system or a wireless control system. Instead of relying on an onboard driver, these vehicles are managed through a remote controller with receiver, enabling operators to transmit commands and receive feedback in real time.

Operators can control vehicles from outside the hazard zone using radio remote control or industrial wireless remote solutions. This approach minimizes risks and increases efficiency, particularly in sectors such as agriculture, mining, logistics, and defense.

Modern remote-control applications often combine teleoperation and autonomy. For example, a machine can navigate independently in standard conditions but it can also allow an operator to take control remotely when a manual decision is required.

The difference between autonomous and connected vehicles

An autonomous vehicle operates independently using onboard intelligence, GPS, sensors, cameras, and algorithms, to make real-time decisions. It follows preprogrammed routes and adapts to its environment without external input.

By contrast, a connected vehicle remains under human supervision via a wireless control system or radio remote-control link. These remote-control systems allow the operator to intervene when conditions become unpredictable or potentially dangerous.

In practice, many industrial vehicles operate in hybrid mode: autonomously for routine tasks, connected for critical ones. This balance between autonomy and teleoperation defines today’s teleoperation technology.

Where are remote-controlled and autonomous vehicles used?

Agriculture and smart farming

Autonomous tractors, sprayers, and harvesters are transforming agriculture. These machines operate with minimal supervision but can be controlled remotely through industrial wireless remote systems or belly boxes for manual intervention. On-vehicle HMI remote panels include pushbuttons, keypads, and selector switches for actions such as start, reset, mode change (manual to remote), or headlight activation. This flexibility allows farmers to manage machines safely and efficiently, even in large or hazardous fields.

From autonomous shuttles to last-mile delivery robots, electric mobility relies heavily on remote-control systems for supervision and intervention. In addition to remote control, some autonomous vehicles can also feature a hidden control panel integrated within the chassis or cabin, allowing a technician or operator to manually take control on site when required. This dual-control configuration, combining wireless teleoperation and local manual override, provides maximum flexibility and safety, ensuring uninterrupted operation, even in the event of a loss of communication or emergency. It also simplifies maintenance and system calibration, as engineers can directly access the vehicle’s functions during inspection or testing phases.

Defense (UGV)

In military contexts, Unmanned Ground Vehicles (UGVs) and Unmanned Aerial Vehicles (UAV) perform missions such as reconnaissance and logistics operations. Operators rely on rugged remote-control components, joysticks, toggle switches, and sealed keypads to maintain precision under extreme conditions. APEM’s HMI remote solutions are designed to meet defense-grade requirements, offering robust tactile feedback and reliability in critical remote-control applications.

Mining and hazardous environments

Mining is a natural field for teleoperation technology. Remote-controlled loaders, drills, and haulage vehicles can be operated from a control room using remote-control radios or remote controller with receiver systems. This approach means that operators are no longer required to enter high-risk areas, reducing exposure to dust, vibration, and gases.

In construction, cranes, concrete pumps, and heavy-duty loaders frequently use remote-control systems. These industrial wireless remote devices (lifting platforms, hook loaders) allow operators to stand at a safe distance while maintaining precise control over load movements. A remote controller with receiver ensures smooth signal transmission between the operator and the machine, while HMI remote interfaces, joysticks, toggle switches, and emergency stops, guarantee intuitive handling and reliable safety management.

Logistics and material handling

In logistics and material handling, AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots) rely on laser scanners and sensors for precise navigation, optimizing goods transportation in warehouses and production lines. When an obstacle arises or a system fault occurs, operators can take control via wireless control systems or teleoperation technology, ensuring safety and continuity. Some vehicles also feature a hidden control panel with HMI remote components, such as sealed pushbuttons or joysticks, allowing manual operation on site for maintenance or emergency situations. This hybrid design combines automation with human supervision for reliable, flexible material handling.

What types of HMI are used with these vehicles?

Remote-controlled and autonomous vehicles integrate several types of Human-Machine Interfaces to support both manual and remote operation modes:

Emergency-Stop switches (E-Stops): “mushroom” pushbuttons that immediately halt the machine for safety purposes.

Remote-control stations: portable control units such as gamepad-style transmitters. These are typically linked to a remote-control receiver, providing proportional control and feedback.

Safety laser scanners on AGVs, laser scanners detect obstacles -people and objects- and enable precise navigation, in complete safety!

In addition to our product line, APEM also offers a range of IDEC solutions, whose “made in Japan” quality already satisfies thousands of customers around the world.

APEM’s expertise in remote-control systems

APEM designs and manufactures robust remote-control components for industrial and mobile machinery. Our HMI solutions deliver intuitive handling and tactile precision for wireless and radio remote-control systems. From agricultural and construction equipment to warehouses, APEM ensures reliable performance even in the harshest environments.

Do you have a remote controller project in mind? Let’s build the right solution together.

Sign up to receive our newsletter, emails about special offers, updates and new releases.

TREND

2024/07/05

PRODUCT

2025/10/21

Product

2025/10/16

Get the help and resources you need quickly with APEM

If you have questions or suggestions, we’re here to listen.

Our sales and support set the standard for helping you.

All the technical documentation you need to make things work...