Atex certification essential for safety in explosive environments

Date: 26/08/2025

Flammable gases, airborne dust, hazardous vapors in many industries: the risk of explosion is ever present. A single spark can be enough to cause a disaster. To prevent such incidents, Europe has implemented a strict standard: ATEX certification. Learn about ATEX.

Flammable gases, airborne dust, hazardous vapors in many industries: the risk of explosion is ever present. A single spark can be enough to cause a disaster. To prevent such incidents, Europe has implemented a strict standard: ATEX certification. Learn about ATEX.

WHAT IS ATEX?

ATEX stands for ATmosphères EXplosibles (Explosive Atmospheres). It refers to two European directives that regulate:

Equipment manufacturing (Directive 2014/34/EU):

requires manufacturers to design products that pose no ignition risk.

On-site use (Directive 1999/92/EC):

defines employer obligations for risk assessment, zoning, and maintenance.

In short, ATEX certification guarantees that a component is safe to use in areas where an explosive atmosphere may occur.

WHERE ARE ATEX -CERTIFIED PRODUCTS USED?

ATEX-certified equipment is required in any area with a potential explosive atmosphere. Common applications include:

Oil refineries and offshore platforms

Petrochemical sites and chemical plants

Agricultural silos and grain processing facilities

Pharmaceutical plants and laboratories

Fuel stations and fuel distribution zones

Specialized vehicles operating in hazardous environments

These environments require control components that are robust and reliable, designed to eliminate any risk of sparks or overheating.

HOW ARE ATEX ZONES CLASSIFIED?

Industrial sites classify hazardous areas based on the likelihood of an explosive atmosphere being present:

Atmosphere Type | ATEX Zone | Presence of Explosive Atmosphere | Practical Example |

Gases / Vapors | Zone 0 | Continuously or frequently present | Inside a fuel tank or gas pipeline |

Gases / Vapors | Zone 1 | Likely to occur in normal operation | Around a gas transfer pump, valve connection |

Gases / Vapors | Zone 2 | Unlikely or only for short duration | Accidental pipe leak, ventilated area near equipment |

Dust | Zone 20 | Continuously or frequently present | Inside a grain silo, dust cyclone |

Dust | Zone 21 | Likely to occur in normal operation | Close to a flour conveyor, bag filling area |

Dust | Zone 22 | Unlikely or only for short duration | Local dust deposit near a hopper or filter |

Components must be selected according to these zones: the higher the risk, the stricter the technical requirements.

These risks have led to the creation of three categories that define the required level of protection for equipment:

CATEGORY 1: VERY HIGH LEVEL OF PROTECTION — an explosive atmosphere is present continuously, for long periods, or frequently.

CATEGORY 2: HIGH LEVEL OF PROTECTION — an explosive atmosphere is likely to occur.

CATEGORY 3: NORMAL LEVEL OF PROTECTION — an explosive atmosphere is unlikely to occur or will persist only for a short period.

ATEX STANDARDS

To achieve ATEX certification, equipment must be designed to:

Prevent any spark or ignition source: requiring precise control of electrical contacts, materials used, and mechanical tolerances.

Withstand extreme conditions: abrasive dust, impacts, vibrations, and temperature fluctuations.

Be tested and validated by an independent notified body.

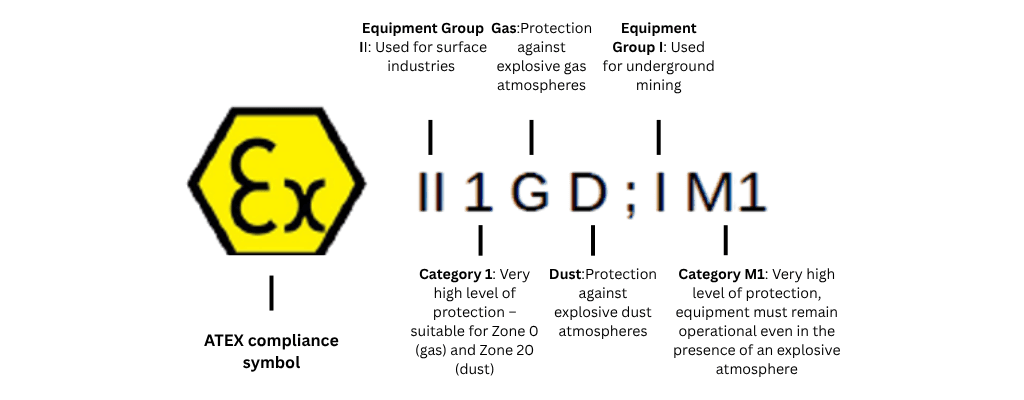

Carry a clear marking: the “Ex” symbol, protection category (1, 2, or 3), gas or dust group, and the intended zone of use.

APEM’S ATEX-CERTIFIED PRODUCTS: PBA SERIES

To meet the specific needs of explosive environments, APEM offers the PBA ATEX series, a range of vandal-resistant pushbuttons. Built for harsh conditions, it combines durability, clean design and ATEX compliance.

Key features of the PBA ATEX series:

Approved according to the ATEX 2014/34/UE directive

Sealed to IP66 (panel-mounted)

Easy-to-clean metal surface

Long life: over 50 million cycles

Illuminated models available

Custom configurations on request

Discover the full specifications of the PBA ATEX series on our website:

DICOVER PBA ATEX

HOW TO CHOOSE AN ATEX HMI

For integrators or operators, a few essential rules apply: Always check the ATEX marking: zone type, gas/dust group, and category.

Request certificates of conformity.

Consider real-life operating conditions (extreme temperatures, immersion, shocks).

Choose reputable, trusted suppliers like APEM, whose expertise in harsh environments guarantees performance and compliance.

DO YOU HAVE A PROJECT IN AN EXPLOSIVE ATMOSPHERE?

Our experts are here to help you choose the perfect solution for your specific environment.

Sign up to receive our newsletter, emails about special offers, updates and new releases.

Get the help and resources you need quickly with APEM

If you have questions or suggestions, we’re here to listen.

Our sales and support set the standard for helping you.

All the technical documentation you need to make things work...