Sealing is a key feature in the choice of a component. But how to choose the right sealing level? The IP rating is a good indicator, provide its meaning is clear.

PRINCIPLES

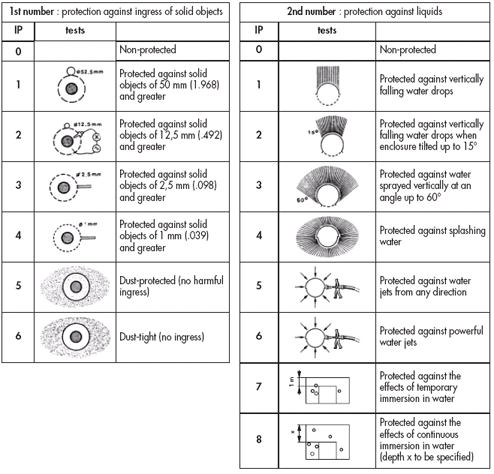

The IP Code (or International Protection Ratingsometimes also interpreted as Ingress Protection Rating) consists of the letters IP followed by two digits and an optional letter. As defined in international standard IEC 60529, it classifies the degrees of protection provided against the intrusion of solid objects (including body parts like hands and fingers), dust, accidental contact, and water in electrical enclosures. The digits (‘characteristic numerals’) indicate conformity with the conditions summarized in the tables below. Where there is no protection rating with regard to one of the criteria, the digit is replaced with the letter X.

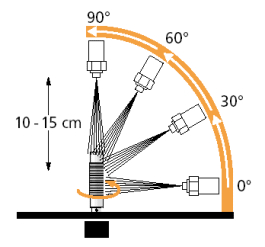

IP69K TEST

The goal of this test is to simulate pressure cleaning conditions on a plant floor.In the test fixture, the switches German standard DIN 40050-9 extends the IEC 60529 rating system with an IP69K rating for high-pressure, high-temperature wash-down applications.Such enclosures must not only be dust tight (IP6X), but also able to withstand high-pressure and steam cleaning. The test specifies a spray nozzle that is fed with 80°C water at 8–10 MPa (80–100 bar) and a flow rate of 14–16 L/min. The nozzle is held 10–15 cm from the tested device at angles of 0°, 30°, 60° and 90° for 30 s each. The test device sits on a turntable that rotates once every 12 s (5 rpm).The IP69K test specification was initially developed for road vehicles, especially those that need regular intensive cleaning (dump trucks, cement mixers, etc), but also finds use in other areas (e.g., food industry).