The XD series has a more advance and complex electronic architecture compare to the other series of joystick.This allows the joystick to continuously perform self-monitoring against any potential internal failure.This capability of running internal diagnostic with redundant element is also related to the SIL2 compatibility.

In the event of internal failure, the XD must react quickly in his diagnostic and behave consequently to inform the system about the anomaly. In the meantime, the remaining functions not impacted by the failure should remain operational for the convenience.The timing and the failure mode in this case are critical to ensure the user’s safety.As a rule, the error code is streamed on the CAN bus within 500ms after the failure occurs.The error code format will be compliant to the J1939-71 as detailed below.

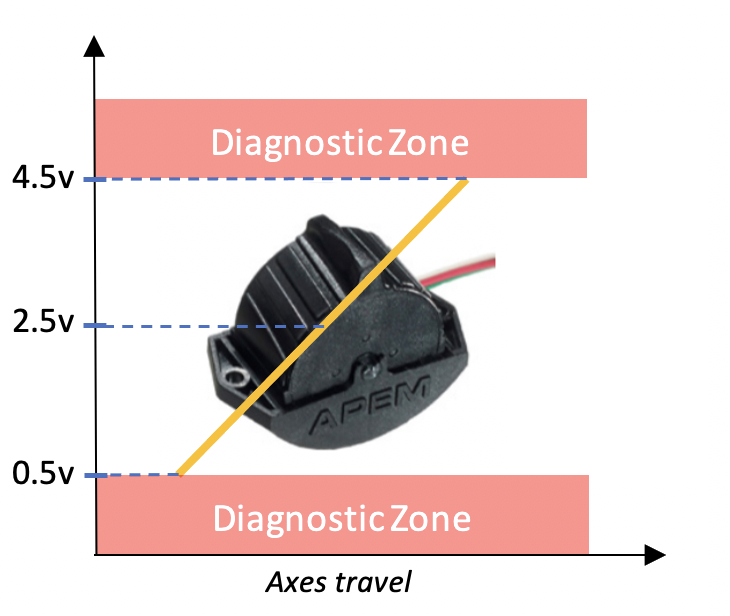

Output outside the operating range

A transient or missing power supply can impact the output of the analog component, as much as if the component get suddenly disconnected from the faceplate, the output will jump straight in the diagnostic zone and the appropriate error code will be triggered for the corresponding component.E.g. with a roller, axis output will be 1022 decimal and the position bit will be 10 decimal.

Loss of communication between the sensor and the CAN controller. If a loss of communication occurs between the main axis sensor and the CAN controller, and the communication does not recover after several attempts, an error code will be triggered on the X and Y axes and their redundancy.E.g. X and Y axis output will be 1022 decimal and all position bit will be 10 decimal.

Loss of communication between the faceplate and the base. A transient or missing power supply can impact the output of the analog component, as much as if the component get suddenly disconnected from the faceplate, the output will jump straight in the diagnostic zone and the appropriate error code will be triggered for the corresponding component.E.g. with a roller, axis output will be 1022 decimal and the position bit will be 10 decimal.

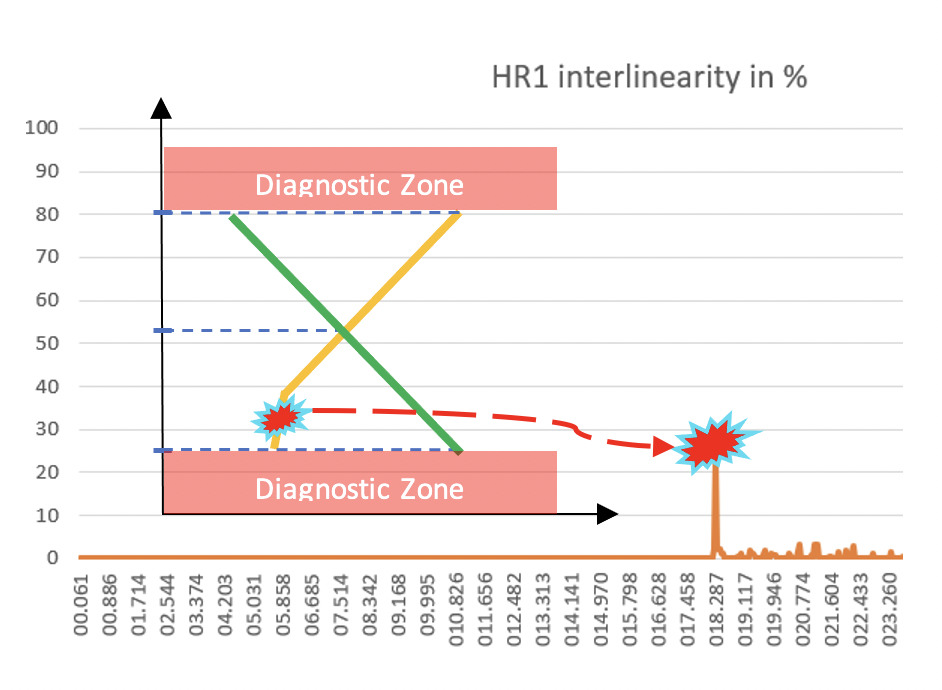

Intern linearity outside tolerance

A transient or missing power supply can impact the output of the analog component, as much as if the component get suddenly disconnected from the faceplate, the output will jump straight in the diagnostic zone and the appropriate error code will be triggered for the corresponding component.E.g. with a roller, axis output will be 1022 decimal and the position bit will be 10 decimal.